Upgrade with IEC EnviroKIT: Sustainable Fan Coil Retrofit Solutions

Providing an elevated customer experience is fundamental to the hospitality industry.

Comfort is king. Guarantee customer happiness with quiet, reliable, comfortable, and efficient HVAC systems. Prevent negative effects on the consumer experience like avoidable repair delays, expensive operational costs, and costly fan coil upgrades.

IEC is the top global provider for fan coil retrofit solutions, offering tailored options to fit any budget and project size.

IEC EnviroKIT's expert engineering enables flexibility to match the performance of existing fan coil units. Replace aging and failing components instead of replacing the complete unit.

Consider five reasons why IEC EnviroKIT vertical stack fan coil kits are the ideal sustainable retrofit solution.

If It Ain't Broke: Alternative to Complete Unit Replacement

Replacing a complete fan coil unit system can be costly.

As a custom option, EnviroKIT is made to work with existing fan coil configurations so that your current units last longer and work better.

The flexible retrofit solution for vertical fan coil applications enables selective component replacement. Only replacing components essential for the operation and improving system performance can reduce the capital budget.

You can repurpose existing components, including cabinets, to significantly reduce initial purchase expense, installation labor, and disposal costs.

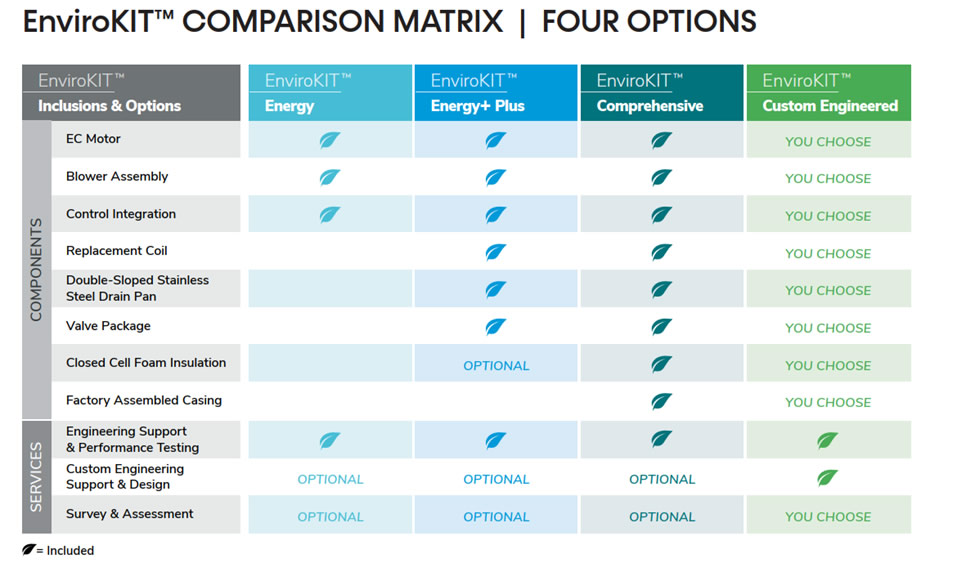

EnviroKIT comes in four tiers to offer flexibility according to your project requirements: Energy, Energy+ Plus, Comprehensive, and Custom Engineered - Refer to Table 1

Rapid Retrofit Reduces Revenue Loss

EnviroKIT from IEC simplifies retrofits - minimized downtime equals maximized savings.

Designed comprehensive kits for quick installation to reduce field labor and speedy return to operation.

Two fan coil units per day can be replaced by a two-person team , reducing the loss of revenue due to the disruption of guest accommodations.

Streamlined installation kit options include energy-saving electrically commutated (EC) motor assemblies, control kits for integration, and factory-assembled chassis comprised of the replacement coil, valve package, and stainless-steel drain pan.

A huge part of the savings is not having to rip the drywall out, which is a 3-4 day process with mudding, sanding, painting, etc. Cuts down on the time a LOT.

Elevated Customized Service for Every Budget

EnviroKITs are available in four tiers to offer customized replacement component solutions tailored to your project budget and scope.

As part of their exceptional service, IEC professionals will complete a unit and site assessment to identify the ideal parts solution for your precise needs and goals.

IEC can provide performance data based on your fan coil unit configuration and needs.

Vertical Savings and Sustainability

Selective component replacement maximizes return on investment (ROI) by significantly improving unit performance and efficiency while extending the life of your fan coil units.

Repurposing and upgrading is more environmentally responsible – and less costly – than unnecessary new manufacturing, which is energy and resource-intensive.

In addition, reducing unnecessary disposal expenses and landfill contributions provides a sustainable alternative to fan coil replacement.

First-Class American Manufacturing

Based in Oklahoma City, OK, IEC takes pride in American engineering, design, manufacturing, and production.

Keeping it homegrown streamlines supply chain challenges while supporting skilled American labor and production.

Redefine Your Risers

Contact our MRG to optimize your vertical fan coil replacement project needs at partscounter@mechanicalresource.com.